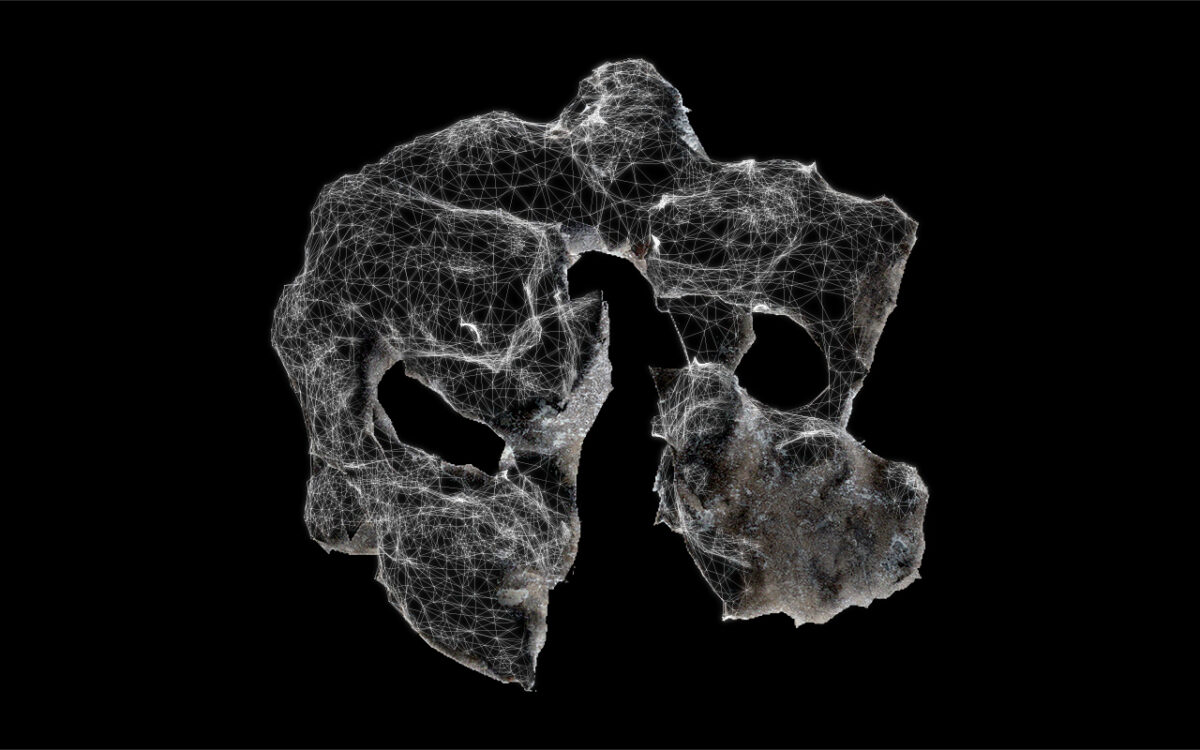

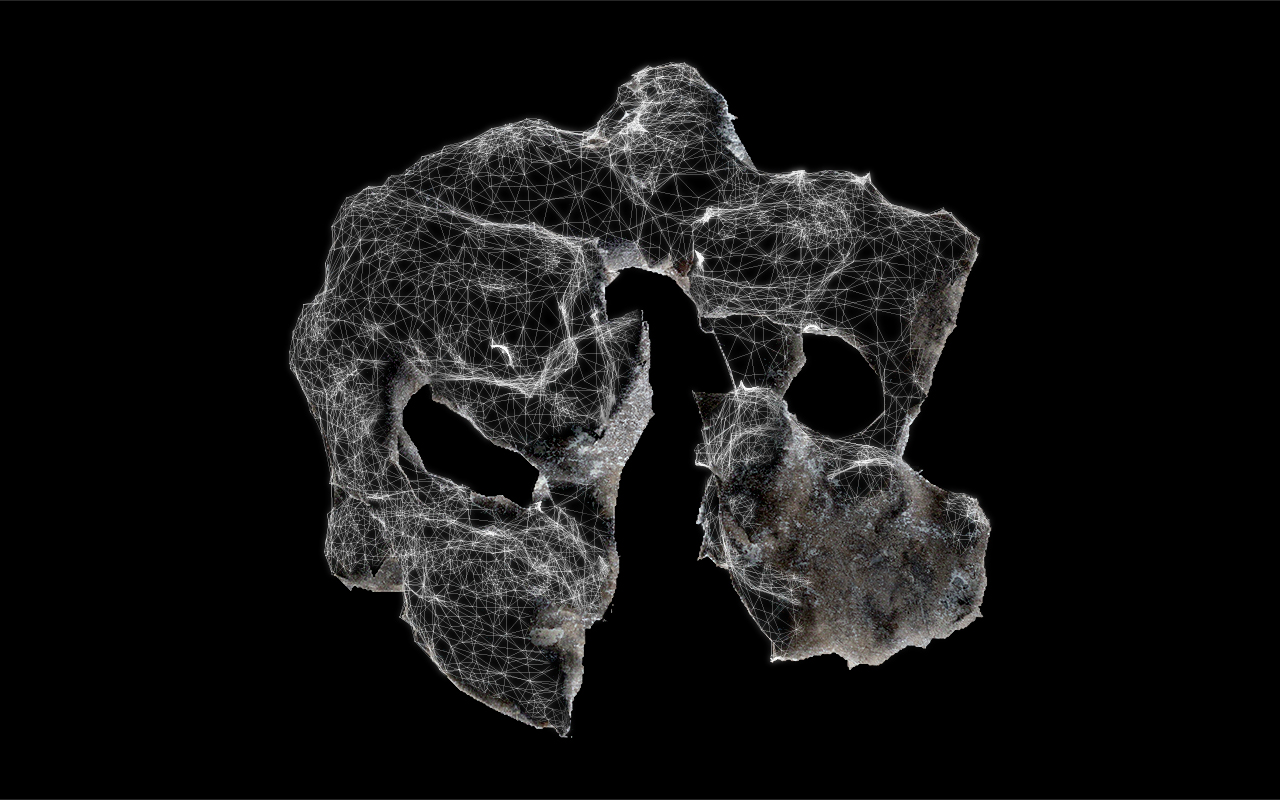

ESR09- SIMULATING CONCRETE FORMWORK

ESR: Vasily Sitnikov

ESR NUMBER: ESR9

INDUSTRIAL PARTNERS: Buro Happold

INSTITUTE: KTH

Simulation of Concrete Casting

Description:

The PhD student will investigate and develop methods for the simulation of formwork in architecture. This will entail research into the transformation between states of fluidity and solidity germane to casting, the dynamic relationship between casting material, formwork and environmental factors, and the architectural possibilities and consequences. The Research will also seek support in the history of formwork and casting in architecture. Current fabrication processes for casting concrete and other composite materials in architecture assumes rigid formwork in order to control geometry and quality. Examples from research explore flexible formwork in order to achieve more variable geometries and resourceful material usage through complex organic shapes. However, these examples are developed through trial and error and rely on empirical testing. This project will develop methods for simulating the dynamic balance between the hydraulic forces of the liquid material and the formwork that counterbalances it, parallel to material testing. By simulating the complex interdependencies and feedback cycles between materials, formwork and environmental parameters during the casting process, new design opportunities emerge. The project will deploy these methods for creating differentiated architectural building elements with a resourceful approach to material use and require a minimum of resources during fabrication.

Vasily Sitnikov

KTH / ESR09- SIMULATING CONCRETE FORMWORK

Vasily Sitnikov is PhD candidate at KTH Royal Institute of Technology, Stockholm. His 4 years spanning research is dedicated to behavior of fresh concrete and means of its digital simulation. Combining physical probes and numeric experiments in the methodology of the investigation, the research aspires to establish a novel concrete casting technology, which intrinsic principals would allow a… read more

Posts

Fabricating Complexity in Concrete with #iceformwork

Author: Vasily Sitnikov

ESR9- SIMULATING CONCRETE FORMWORK AUTHOR: VASILY SITNIKOV In order to minimize the amount of cement involved in concrete constructions, the concrete industry today chooses to reduce the share of cement in the total mass of concrete. This approach leads to lower mechanical properties of concrete, resulting in thicker floor slabs and massive beams. An... read more

Keywords: · concrete casting · digital simulation · formwork4concrete · free complexity · freeform · iceformwork · material performance · material science · postdigital · UHPC

#iceformwork – A New Type of Formwork for Ultra-High Performance Concrete

Author: Vasily Sitnikov

ESR9- SIMULATING CONCRETE FORMWORK AUTHOR: VASILY SITNIKOV To increase performance of concrete constructions, concrete industry chooses to reduce the amount of cement in concrete they use. This approach leads to lower mechanical properties of concrete, resulting in thicker floor slabs and massive beams. An alternative strategy is to increase the share of cement in... read more

Keywords: · concrete casting · digital simulation · formwork4concrete · free complexity · freeform · iceformwork · material performance · material science · postdigital · UHPC

Trial Procedure

Author: Vasily Sitnikov

ESR9- SIMULATING CONCRETE FORMWORK AUTHOR: VASILY SITNIKOV Concrete is the most used material in the world. This simple fact preconditions a countless variety of technologies that branch in all thinkable ways from the very basic concept of casting. Besides an ever extending catalog of mixture compositions based on cement binders, the formwork itself is... read more

Keywords: · concrete casting · digital simulation · formwork4concrete · free complexity · freeform · material performance · material science · postdigital