Current methods for materialisation within the building industry are based on mass production. They rely on the standardisation of material and fabrication to afford control and optimise material use. With digitisation these methods become outdated and new models for material optimisation emerge. Where subtractive digital fabrication techniques have matured and been applied to realise complex buildings, recent research efforts utilise bespoke machines or industrial robots as general fabrication tools for additive fabrication to innovate mass customised materials with designed performances.

The topic is tackled in the innochain Work package 5 , which will focus on trialling fabrication and planning methods for new designed materials that embed material optimisation within their composition.

The workpackage is lead by the The Bartlett School of Architecture / University College London

research projects

ESR11- Concrete Deposition

Author: Helena Westerlind

Generally, applied digital fabrication technologies are subtractive causing material waste at fabrication level. New research explores additive processes in building realization creating more sustainable and materially smart solutions. read more

Keywords: · concrete · deposition · material resolution

ESR12- MATERIAL GRADIENT FRP

Author: Saman Saffarian

Current practices emphasise the stiffness of material to ensure structural performance. Building systems such as louvers or other adjustable shading systems and employ mechanical means to activate change. read more

Keywords: · Climate Adaptive Building Envelopes · Kinetic Elastic Facade · Material Gradient FRP

ESR13- APPLIED ROBOTICS – CONTROLLED MATERIAL DEPOSITION

Author: Arthur Prior

Industrial modelling clay plays an important role in automotive design when modelling ‘class-A’ surfaces. Design studios around the world use it to prototype vehicles at a 1:1 scale, combining several technologies: sculpting, CAD freeform surface modelling, 3D scanning and CNC machining. This research investigates the use of this material for additive manufacturing. read more

Keywords: · Additive and Subtractive Manufacturing · Controlled Material Deposition · Industrial Modelling Clay

ESR14- DESIGN FOR ASSEMBLY

Author: Ayoub Lharchi

Industrial Partners: designtoproduction, Bluhmer Lehmann. One of the central achievements of digital chain is the ability to mass customise building elements creating individualised solutions and enabling new kinds of building geometries. While methods for the design and production of customised elements have matured, the planning of assembly procedures remains undeveloped in the building sector – in contrast to for example to product design . read more

Keywords: · Design for manufacture and assembly · Mass Customisation · timber

ESR15 – SMALL SCALE ROBOTIC MANUFACTURING FOR THE LARGE SCALE BUILDINGS

Author: Stephanie Chaltiel

Digital fabrication presumes prefabrication and off-site production. This has vast implications on the environment and building practice as a whole, as transportation increases energy consumption and carbon footprint and logistics necessitate a building logic based on elements effecting problems of tolerances and loosing structural and thermal advantages of monolithic structures while increasing costs and limiting the size of elements. read more

Keywords: · 3dprint · earth architecture · parametric vernacular · robots · robots in architecture

FlectoFold / Materialisation & Evaluation Process

Author: Saman Saffarian

ESR12- MATERIAL GRADIENT FRP AUTHOR: Saman Saffarian FlectoFold is an Elastic-Kinetic Material-Gradient facade component. This video showcases the Materialisation and Evaluation Process. read more

Keywords: · Climate Adpative Building Envelope · GFRP · Kinetic Elastic · Material Gradient

ARTICLES

Welfare Panels

Author: Helena Westerlind

Tensta Konstall, Stockholm 10.10.2017-14.01.2018 Erik Stenberg, Helena Westerlind Pedro Ignacio Alonso, Hugo Palmarola, José Hernández Photo by Jean-Baptiste Beranger Animated poster (José Hernández and Helena Westerlind) Photo by Jean-Baptiste Beranger Photo by Jean-Baptiste Beranger Assembly of Soviet system I-464 (José Hernández and Helena Westerlind) Exhibition... read more

Keywords:

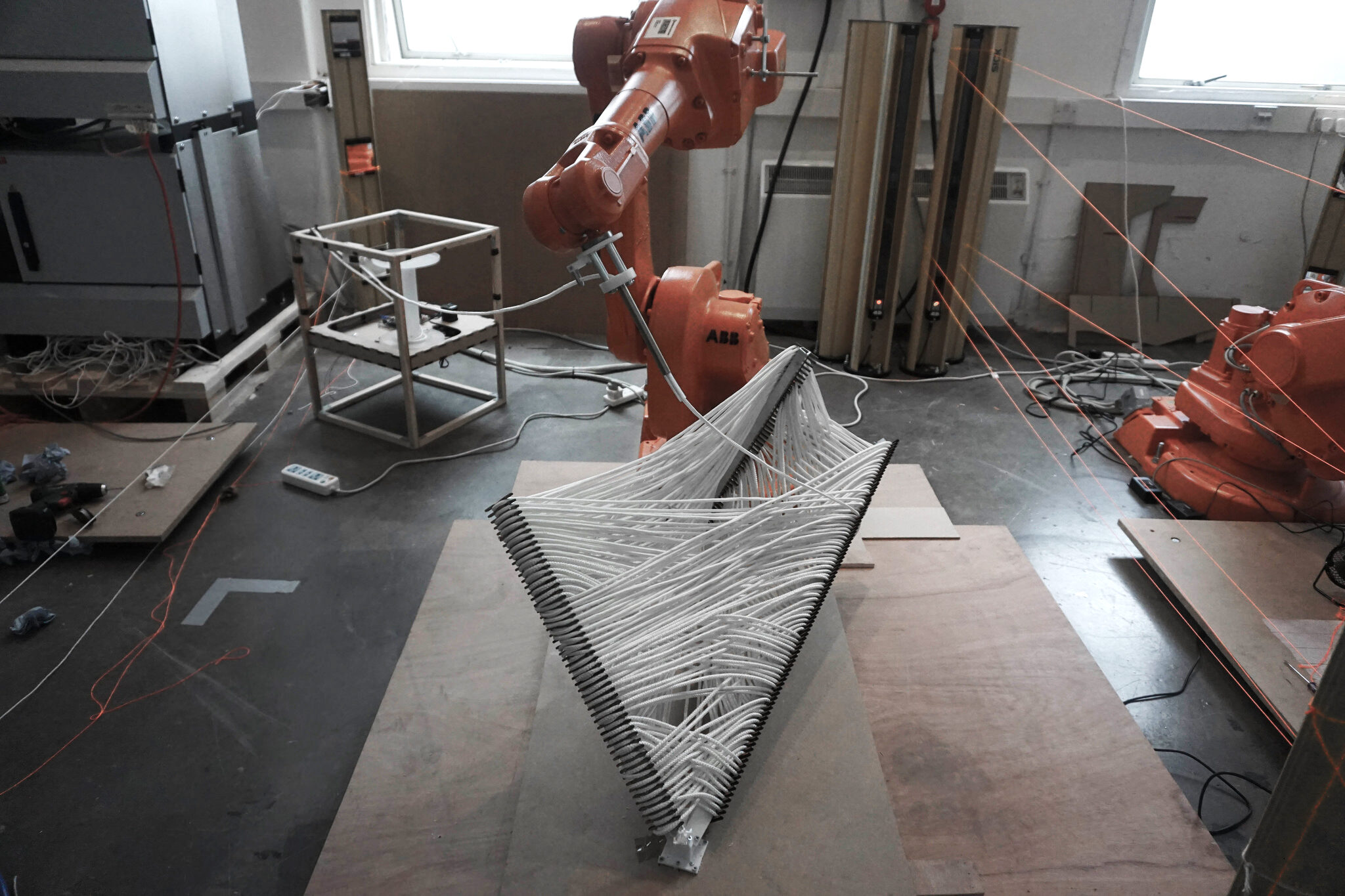

Acadia 2017, Boston: Paper Presented on the ICD/ITKE Research Pavilion 2016/2017

Author: James Solly

Acadia 2017 James (ESR08) and Sam (ESR12) both attended the Acadia 2017 “Disciplines and Disruption” Conference at MIT in Boston, 2nd-4th November 2017. During the conference, our colleagues from the ICD (Institute of Computational Design and Construction) presented the paper: Multi-Machine Fabrication: An Integrative Design Process Utilising an Autonomous UAV and Industrial Robots for the... read more

Keywords: · CFRP · Coreless Fibre Winding · GFRP · itke

ACADIA Autodesk 2017 Research Project Award

Author: Stephanie Chaltiel

The Monolithic Earthen Shells project recieves the ACADIA Autodesk 2017 award for Emerging research. Authors: Stephanie Chaltiel and Maite Bravo are very honoured to recieve the prize. Extract from the ACADIA 2017 proceeding on the Earthen Shells project: This project explores the implementation of additive manufacturing for monolithic shells, based on the deposition of different... read more

Keywords: · ACADIA · autodesk · award · earthen shells · robotic fabrication

Scientific Papers and Public talks: Monolithic Earthen Shells & Robotic Fabrication

Author: Stephanie Chaltiel

The Monolithic Shells robotic Fabrication project has been published in 7 international conferences recently including: in the proceedings of IASS Hamburg 2017, Ecaade Roma 2017, DMSParis 2017, Fab 13 Santiago de Chile, ACADIA MIT Boston. Most have been presented live including the challenging #Pechakucha of IASS Here you can download the PDF of IASS. 10162_manuscript and most... read more

FlectoFold Demonstrator / BauBionik Exhibition / Stuttgart

Author: Saman Saffarian

Design Development, prototyping, evaluation, fabrication & installation of an Elastic-Kinetic Material-Gradient Facade Shading System : FlectoFold This Large scale demonstrator is being exhibited as part of BauBionik Exhibition opening today at Schloss Rosenstein in Stuttgart, Germany. read more

Keywords: · CFRP Lamination · Elastic Kinetic Facade · Facade Demonstrator · itke · Material Gradient FRP